Understanding Water Discount in Soap Making: A Comprehensive Guide

Calculating water discount is the process of determining the amount of water that can be deducted from the total weight of the soap batter to account for the moisture content in the final product. Water discount is crucial in soap making as it ensures accurate formulation, affects the texture and quality of the soap, and helps optimize production costs. Historically, soap makers relied on traditional methods to approximate water discount. Today, scientific advancements and standardized formulations have led to more precise calculation techniques.

This article will explore the essential elements of calculating water discount in soap making, including the factors that influence it, the various methods used, and the impact of different techniques on the final product. It will provide valuable insights for soap makers of all levels, helping them create consistent, high-quality soaps with optimal performance.

How to Calculate Water Discount in Soap Making

Water discount is an essential aspect of soap making as it directly impacts the final quality and consistency of the soap. Key aspects to consider when calculating water discount include:

- Desired hardness: Soft soaps require more water discount than hard soaps.

- Type of oils used: Different oils have different water absorption rates.

- Additives: Some additives, such as clays and exfoliants, can affect water discount.

- Curing time: Longer curing times can reduce the amount of water discount needed.

- Climate: Humidity can influence the rate of evaporation.

- Formulation: The balance of oils, water, and lye will affect water discount.

- Equipment: Different methods of soap making may require adjustments to water discount.

- Experience: Soap makers with experience can often estimate water discount more accurately.

- Trial and error: Testing different water discount percentages is often necessary to find the optimal amount.

Understanding these aspects allows soap makers to calculate water discount precisely, ensuring that their soaps have the desired properties and perform as intended. Accurate water discount calculation contributes to the creation of high-quality, consistent soaps that meet the expectations of consumers.

Desired hardness

In the context of soap making, water discount plays a crucial role in determining the final hardness or softness of the soap. Understanding the relationship between desired hardness and water discount is essential for achieving the intended properties and performance of the soap.

- Oil selection

The type of oils used in soap making significantly influences water discount. Soft oils, such as olive oil and coconut oil, require a higher water discount than hard oils, such as palm oil and castor oil. This is because soft oils absorb more water during the saponification process.

- Additives

The addition of certain ingredients, such as clays and exfoliants, can also affect water discount. These additives can absorb water, reducing the amount of water that needs to be discounted.

- Curing time

The length of time that the soap cures can impact water discount. Soaps that are cured for longer periods of time will lose more water through evaporation, resulting in a lower water discount.

- Formulation

The overall formulation of the soap, including the balance of oils, water, and lye, will influence water discount. A higher proportion of water in the formulation will require a greater water discount.

By considering these factors and understanding the relationship between desired hardness and water discount, soap makers can accurately calculate the appropriate water discount for their specific formulations, ensuring that their soaps have the desired hardness and meet the expectations of consumers.

Type of oils used

The type of oils used in soap making significantly influences the water discount calculation. Different oils have varying water absorption rates, impacting the amount of water that needs to be deducted from the total weight of the soap batter. Oils with higher water absorption rates, such as olive oil and coconut oil, require a greater water discount compared to oils with lower water absorption rates, like palm oil and castor oil.

This variation in water absorption rates stems from the molecular structure and composition of the oils. Oils with a higher proportion of unsaturated fatty acids, such as olive oil, tend to absorb more water than oils with a higher proportion of saturated fatty acids, like palm oil. The presence of hydrophilic (water-loving) functional groups in the oil molecules also contributes to their water absorption capacity.

Understanding the water absorption rates of different oils is crucial for accurate water discount calculation. By considering the specific oils used in a soap recipe, soap makers can determine the appropriate water discount to ensure the final soap has the desired hardness and performance. This knowledge empowers soap makers to create consistent, high-quality soaps that meet the expectations of consumers.

Additives

In the context of soap making, understanding the effect of additives on water discount is crucial for achieving the desired properties and performance of the final soap. Additives, such as clays and exfoliants, can significantly influence the amount of water that needs to be discounted from the total weight of the soap batter.

The presence of additives in soap recipes introduces additional factors that affect water absorption and evaporation rates. Clays, for example, have a high water absorption capacity due to their porous structure and hydrophilic nature. When added to soap batter, clays absorb water, reducing the amount of free water available for evaporation during curing. Exfoliants, on the other hand, can have a varying impact on water discount depending on their composition and particle size. Some exfoliants, like finely ground oatmeal, can absorb water, while others, like salt or sugar, can draw water out of the soap batter.

Understanding the specific effects of different additives on water discount is essential for soap makers to accurately calculate the appropriate water discount percentage. By considering the type and quantity of additives used in a particular soap recipe, soap makers can ensure that the final soap has the desired hardness, lather, and performance characteristics. This knowledge empowers soap makers to create consistent, high-quality soaps that meet the expectations of consumers.

Curing time

In the context of soap making, curing time plays a crucial role in determining the final water discount calculation. Curing refers to the process of allowing the soap to age and harden after it has been made. During this period, the soap undergoes various chemical and physical changes that affect its moisture content and overall properties.

One of the key effects of curing time is the reduction in moisture content. As the soap cures, water evaporates from the soap, resulting in a decrease in the overall weight of the soap. This loss of moisture directly impacts the water discount calculation. A longer curing time allows for more water to evaporate, reducing the amount of water that needs to be discounted from the total weight of the soap batter.

Understanding the relationship between curing time and water discount is essential for soap makers to accurately calculate the appropriate water discount percentage. By considering the intended curing time for a particular soap recipe, soap makers can ensure that the final soap has the desired hardness, lather, and performance characteristics. This knowledge empowers soap makers to create consistent, high-quality soaps that meet the expectations of consumers.

Climate

In the context of soap making, understanding the impact of climate and humidity on the rate of evaporation is essential for accurate water discount calculation. Climate plays a crucial role in determining the moisture content and curing time of the soap, which directly affects the amount of water that needs to be discounted from the total weight of the soap batter. Humidity, in particular, has a significant influence on the rate of evaporation during the curing process.

In humid environments, the air contains a higher concentration of water vapor, which slows down the evaporation process. This means that soaps made in humid climates will retain more moisture and require a higher water discount compared to soaps made in dry climates. Conversely, in dry climates, the air has a lower concentration of water vapor, resulting in a faster evaporation rate. Soaps made in dry climates will lose moisture more quickly, requiring a lower water discount.

Understanding the relationship between climate, humidity, and water discount is crucial for soap makers to achieve consistent results. By considering the specific climate conditions in which the soap will be made and cured, soap makers can determine the appropriate water discount percentage to ensure the final soap has the desired hardness, lather, and performance characteristics. This knowledge empowers soap makers to create high-quality soaps that are well-suited to their intended environment.

Formulation

In the context of soap making, understanding the formulation and the balance of oils, water, and lye is crucial for calculating water discount accurately. The formulation of a soap recipe directly influences the amount of water that needs to be discounted from the total weight of the soap batter.

- Oil Selection

The type and proportion of oils used in a soap recipe will affect water discount. Oils with higher water absorption rates, such as olive oil and coconut oil, require a greater water discount compared to oils with lower water absorption rates, like palm oil and castor oil.

- Water Content

The amount of water added to the soap batter will directly impact the water discount. A higher proportion of water in the formulation will require a greater water discount to achieve the desired final hardness of the soap.

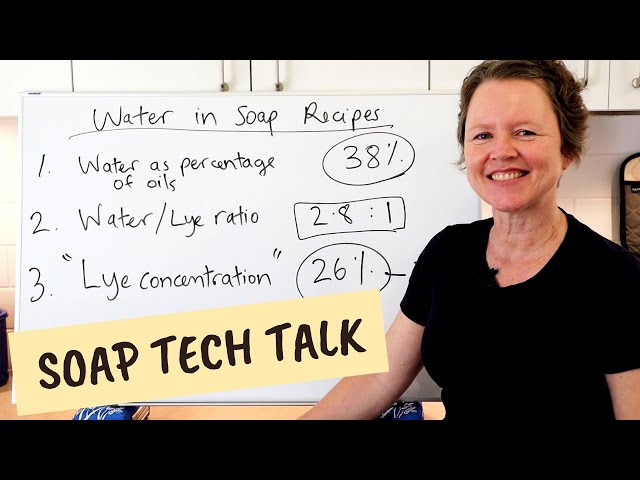

- Lye Concentration

The concentration of lye used in the soap making process will also affect water discount. A higher lye concentration will result in a harder soap, which requires a lower water discount.

- Additives

The presence of additives, such as clays and exfoliants, can also influence water discount. These additives can absorb water, reducing the amount of free water available for evaporation during curing.

By carefully considering the formulation and the balance of oils, water, and lye, soap makers can accurately calculate the appropriate water discount percentage. This ensures that the final soap has the desired hardness, lather, and performance characteristics, meeting the expectations of consumers.

Equipment

When calculating water discount in soap making, it is crucial to consider the equipment used, as different methods may require adjustments to ensure accurate results. Equipment can influence water discount in several ways:

- Mold Type

The type of mold used can affect water loss during the curing process. For instance, silicone molds tend to retain more moisture than plastic molds, requiring a lower water discount.

- Cutting Method

The method of cutting the soap can also impact water discount. Soaps cut with a wire cutter may have a lower water discount compared to those cut with a knife, as the wire can remove excess water more effectively.

- Curing Environment

The curing environment, including factors such as temperature and humidity, can be influenced by the equipment used. A controlled curing environment can help regulate moisture loss, affecting the water discount calculation.

- Batch Size

The size of the soap batch can also be a factor. Larger batches may require a higher water discount to compensate for the increased surface area exposed to evaporation.

Understanding the impact of equipment on water discount allows soap makers to adjust their calculations accordingly. By considering the specific equipment and techniques used, they can ensure accurate water discount calculations, resulting in consistent and high-quality soaps.

Experience

In the realm of soap making, experience plays a pivotal role in accurately calculating water discount. Soap makers who have honed their craft over time develop an intuitive understanding of the complex factors that influence water discount, enabling them to estimate it with greater precision.

- Familiarity with Ingredients and Properties

Experienced soap makers possess an in-depth knowledge of the properties of different soap-making ingredients, including their water absorption rates. This allows them to anticipate how each ingredient will affect the overall water content of the soap batter.

- Trial and Error

Through countless batches of soap, experienced soap makers have accumulated a wealth of practical knowledge. This hands-on experience provides them with valuable insights into the effects of different formulations and techniques on water discount.

- Understanding of Curing Process

The curing process significantly impacts a soap’s final moisture content. Experienced soap makers have a deep understanding of the factors that influence curing, such as temperature and humidity, allowing them to adjust water discount accordingly.

- Sensory Evaluation

With practice, soap makers develop a keen ability to assess the consistency and texture of soap batter. This sensory evaluation helps them determine the appropriate water discount, ensuring the final soap has the desired hardness and lather.

By leveraging their knowledge, experience, and intuition, seasoned soap makers can estimate water discount with remarkable accuracy. This expertise contributes to the creation of consistent, high-quality soaps that meet the desired specifications and delight consumers.

Trial and error

In the intricate world of soap making, calculating water discount with precision is a crucial step towards achieving the desired soap characteristics. Trial and error, involving the testing of various water discount percentages, plays a pivotal role in this process, as it allows soap makers to fine-tune their formulations and techniques to attain the optimal outcome.

Water discount directly influences the final hardness and performance of the soap. By experimenting with different water discount percentages, soap makers can determine the ideal amount that will yield a soap with the desired consistency, lather, and cleansing properties. This iterative approach enables them to compensate for variations in the ingredients, environmental conditions, and their unique soap-making methods.

Real-life examples abound in the soap-making community. A soap maker may start with a basic recipe and gradually adjust the water discount percentage in subsequent batches, observing the resulting changes in the soap’s texture, appearance, and performance. Through this trial-and-error process, they can refine their recipe over time, accumulating valuable knowledge and expertise.

The practical applications of this understanding are evident in the consistent production of high-quality soaps. By embracing trial and error, soap makers can avoid common pitfalls, such as overly soft or hard soaps, poor lathering, or unsatisfactory cleansing abilities. This meticulous approach empowers them to create soaps that meet specific customer needs and preferences.

Frequently Asked Questions about Calculating Water Discount in Soap Making

This section addresses commonly asked questions and clarifies essential aspects of calculating water discount in soap making, providing valuable insights for both novice and experienced soap makers.

Question 1: What is the purpose of calculating water discount?

Calculating water discount ensures accurate soap formulation, affects the texture and quality of the final product, and helps optimize production costs.

Question 2: What factors influence water discount?

Water discount is influenced by desired soap hardness, type of oils used, additives, curing time, climate, overall formulation, equipment, and the soap maker’s experience.

Question 3: Why is it important to consider the type of oils used when calculating water discount?

Different oils have varying water absorption rates, impacting the amount of water that needs to be discounted. Soft oils, such as olive oil, require a higher water discount than hard oils, like palm oil.

Question 4: How does curing time affect water discount?

Longer curing times can reduce the amount of water discount needed as the soap loses moisture through evaporation during the curing process.

Question 5: What role does climate play in water discount calculation?

Climate, particularly humidity, influences the rate of evaporation during curing. Soaps made in humid environments require a higher water discount compared to those made in dry climates.

Question 6: Is trial and error necessary when calculating water discount?

Trial and error is often necessary to find the optimal water discount percentage for a specific formulation and set of conditions. By testing different percentages, soap makers can fine-tune their recipes and achieve the desired soap characteristics.

These FAQs provide a solid foundation for understanding the importance and intricacies of calculating water discount in soap making. In the next section, we will delve deeper into the practical applications of water discount calculations and explore techniques for optimizing soap formulations.

Continue reading about Practical Applications of Water Discount Calculations

Tips for Calculating Water Discount in Soap Making

Precise water discount calculation is essential for successful soap making. Here are some practical tips to help you achieve accurate results:

Tip 1: Understand the Factors

Consider the type of oils, desired hardness, additives, and curing time to determine the appropriate water discount.

Tip 2: Use a Water Discount Calculator

Online calculators can provide a starting point for your calculations, but always adjust based on your specific ingredients and conditions.

Tip 3: Start with a Small Batch

Create a small test batch to experiment with different water discount percentages before committing to a large batch.

Tip 4: Monitor the Curing Process

Observe the soap as it cures to assess its hardness and moisture content. Adjust the water discount accordingly for future batches.

Tip 5: Keep a Soap-Making Journal

Record your experiments, including the water discount used, to build a database for future reference and improvements.

Tip 6: Seek Guidance from Experienced Soap Makers

Connect with other soap makers to learn from their experiences and insights.

Summary: By following these tips, you can refine your water discount calculations, leading to consistent, high-quality soaps that meet your desired specifications.

These practical tips provide a foundation for exploring the intricacies of water discount calculations. In the next section, we will delve into advanced techniques for optimizing soap formulations and troubleshooting common challenges.

Conclusion

This article has provided a comprehensive exploration of water discount calculation in soap making, exploring the factors that influence it, the methods used to calculate it, and the impact of different techniques on the final product. Key insights include the importance of considering the type of oils used, desired hardness, additives, curing time, and climate when determining water discount. Additionally, understanding the relationship between water discount and the formulation and equipment used is crucial for accurate calculations.

Trial and error, combined with experience and knowledge of soap-making principles, enables soap makers to refine their water discount calculations and create consistent, high-quality soaps that meet specific requirements. By embracing scientific principles and practical experimentation, soap makers can elevate their craft and produce soaps that are not only aesthetically pleasing but also effective and long-lasting. The precise calculation of water discount remains a cornerstone of successful soap making, ensuring that the final product meets the desired specifications and delights consumers.